Stainless Steel Press Female Thread Coupling

Size Range: 1/4"×1/2Rp/in~2"×2Rp/in (DN10×1/2Rp/in~DN50×2Rp/in)

Thickness:0.6~2MM

Standards: GB/T19228.2-2011 CJ/T 152-2016 CJ/T466-2014 EN DIN ASME

Material: SS304 SUS304 1.4301,SS316 SUS316 1.4401,TP304L 1.4306,TP316L 1.4404.

Ring Gasket Material: CIIR, EPDM,PTFE, Nitrile.

Type: A type and B type;

Connection Mode of Socket End: D Type and S Type;

Stainless Steel Press Female Thread Coupling

Size Range: 1/4"×1/2Rp/in~2"×2Rp/in (DN10×1/2Rp/in~DN50×2Rp/in)

Thickness:0.6~2MM

Standards: GB/T19228.2-2011 CJ/T 152-2016 CJ/T466-2014 EN DIN ASME

Material: SS304 SUS304 1.4301,SS316 SUS316 1.4401,TP304L 1.4306,TP316L 1.4404.

Ring Gasket Material: CIIR, EPDM,PTFE, Nitrile.

Type: A type and B type;

Connection Mode of Socket End: D Type and S Type;

Process:Pipes - Mechanically formed and Weld;

Packing: Plastic bags+ Cartons + Wooden Case;

Product Marking: Size and Material (According to customer requirements.);

Certificates: GB/T19001-2016,ISO9001:2015,CE, Sanitary License ;

Medium: Drinking water, wastewater, industrial water, gas.

Application: Engineering projects, Ships, Commercial Buildings, Residential Buildings, Hospitals, Hotels, Environmental Protection, Heating, Air conditioning, etc

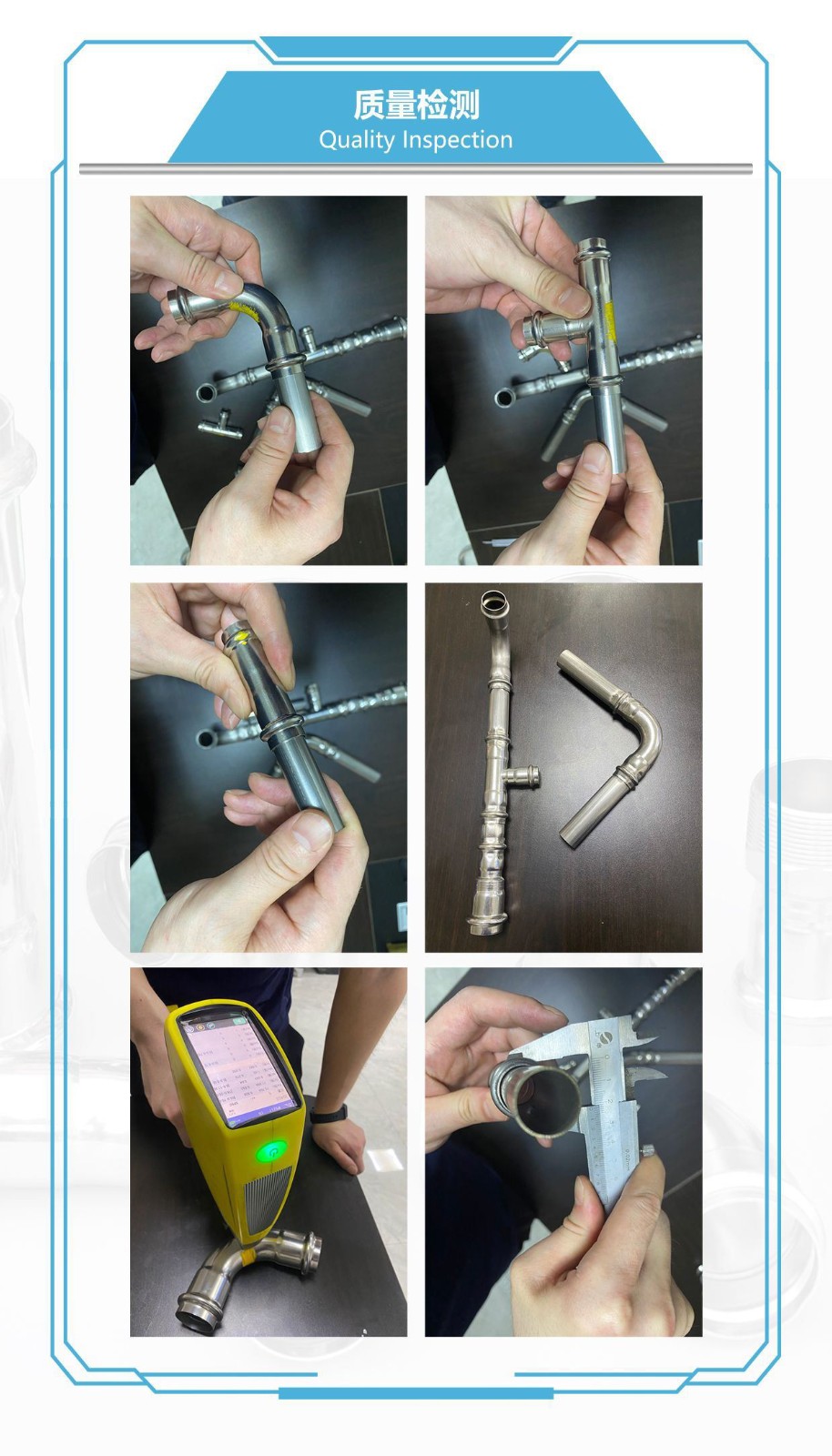

Test Items:

Hydrostatic test, Airtight test, Pressure test, Negative Pressure test, Drawing Test, Temperature change (cold and hot water cycle) test, Hydrostatic bending and Torsion test, Hydrostatic vibration test, Hydrostatic impact test.

Product Quality Control: We have QC person stay on the production lines do to the inspection. All products must have been inspected before delivery. we do online inspection and final inspection.

1. Raw material outside diameter thickness material inspection;

2. The length and end of raw materials shall be inspected after cutting;

3. After machine processing, the socket, outside diameter and thickness are checked;

4. The weld size surface shall be inspected after welding forming.

5. After heat treatment, the surface, size and socket shall be inspected.

6. After surface treatment, check whether the surface is qualified.

7. 100% Hydraulic air tightness test.

8. Marking and Packaging inspection.

Production Equipment: 1 Laser cutting machine,1 Vibrator machine, 1 Bench drill,1 Column hydraulic press, 1 Frame hydraulic press, 1 Hydraulic high speed punching machine, 1 Hydraulic tee drawing machine, 1 Automatic argon arc welding machine,1 Automatic hydraulic pipe bender, 1 Laser typewriter, 1 1 CNC lathe,1 Packaging machine and other equipment.

HS Code: 7307230000

FAQ

What’s Your MOQ?

5~10PCS, There are 5000PCS in stock for each product and each size. Can support delivery at any time.

How Long Is Your Delivery Time?

The general delivery time is 20-30 days after receiving your order confirmation. Anther, if we have the goods in stock, it will only take 3-5 days.

Can We Print Our Own Logo?

Yes,we offer OEM service.

How Your Quality Guarantee?

We have 100% quality guarantee to customers. We will be responsible for any quality problem.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Miss Xu

Phone: +86-13587106106

E-mail: Mandy@zimifitting.com

Add: Zhejiang West Hardware market,Quzhou City,Zhejiang,China