Overview

The Stainless Steel 1pc Thread Ball Valve is an accessory for pipelines. It closes tightly with only 90 degrees of rotation and a small turning torque. The inner cavity of the valve body can ensure the direct passage of the medium. Its valve body can be integral or combined. The Stainless Steel 1pc Thread Ball Valve can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, slurries, oils, liquid metals and radioactive media.

The main feature of the Stainless Steel 1pc Thread Ball Valve is its inherent compactness and ease of operation and maintenance. Its sealing surface and spherical surface are often in a closed state, so it is not easily eroded by the medium and is easy to operate and maintain. In addition, the inner wall is polished smooth and has a low flow resistance, so there is no need to worry about it affecting the flow rate of the medium in the pipe.

Specification

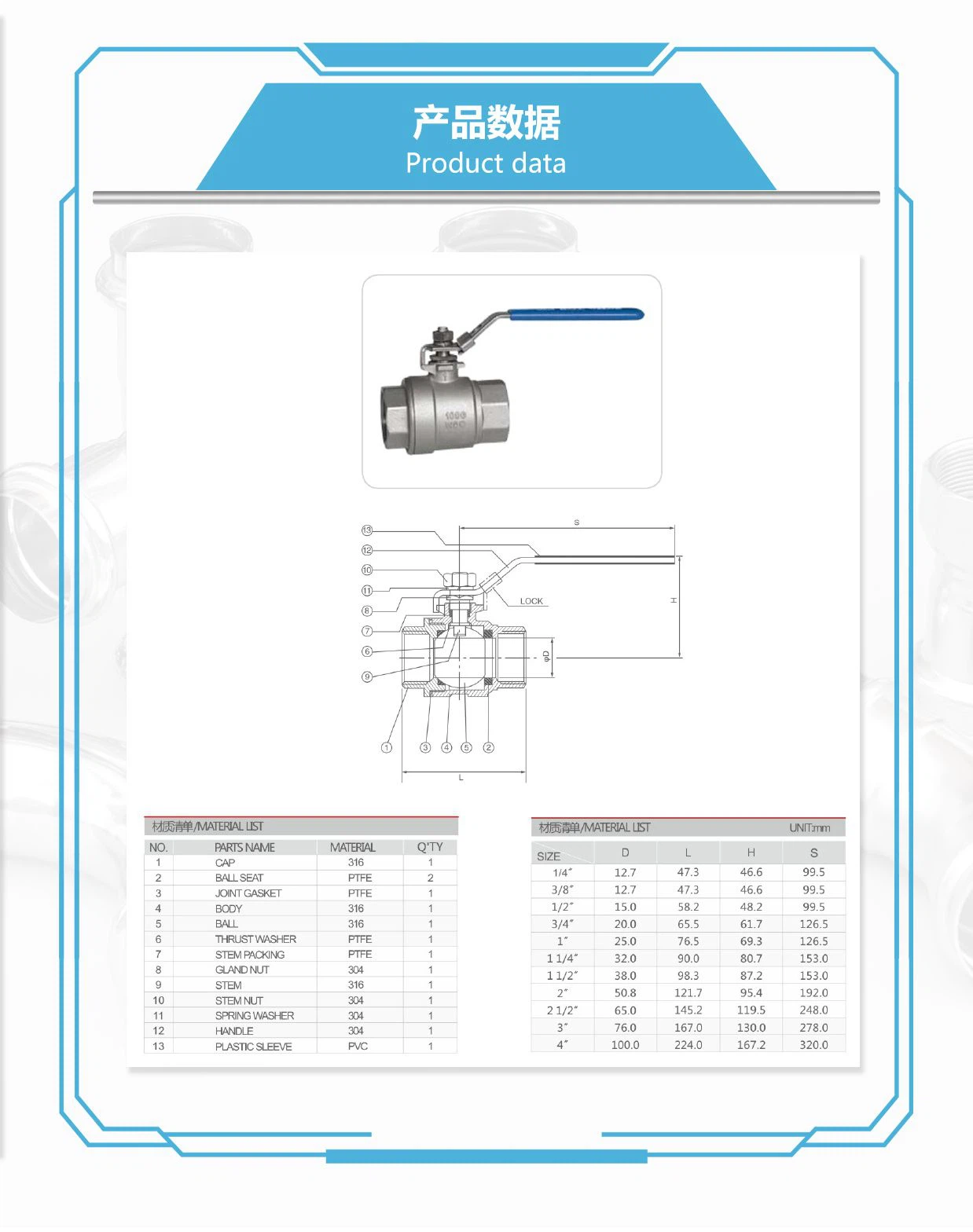

Size: 1/4"to 4"(DN8-DN100) Full Bore

End connection: BSPT BSP NPT Female Threaded, DIN259/2999,ISO 228

Working Pressure: 1000PSI for W.O.G

Process:Investment Casting Body-CNC lathe processing.

Blow-out proof stem

Operation: Manual(Lock Lever Handle Avaliable)

Adjustable stem packing

Temperature range: -60 to 450°

Pure teflon seals and seats

100% leakage tested at 100PSI air under water

Material: Valve Body-SS304(CF8,SUS304,1.4308),SS316(CF8M,SUS316,1.4408), SS304L,SS316L

Handles and Nuts: SS201,SS304,SS316(According to customer needs)

Technical Features:

Working Pressure: 1000PSI for W.O.G

Process:Investment Casting Body-CNC lathe processing.

Blow-out proof stem

Operation: Manual(Lock Lever Handle Avaliable)

Adjustable stem packing

Temperature range: -60 to 450°

Pure teflon seals and seats

100% leakage tested at 100PSI air under water

Material: Valve Body-SS304(CF8,SUS304,1.4308),SS316(CF8M,SUS316,1.4408), SS304L,SS316L

Handles and Nuts: SS201,SS304,SS316(According to customer needs)

HS Code: 8481.804090

Certificates: GB/T19001-2016 ISO9001:2015 、CE

Test Certificates:

EN 10204/3.1B-MTC

Raw material inspection certificate.

100% Radiography Test Report

Hydraulic seal test report.

Thread inspection report

Third Party Inspection Report, etc

QC:

1. All raw materials will be inspected as soon as they arrive in our factory.

2. All parts, logos and all details that will be checked during the production process.

3. Check all packaging details during production.

4. After completion, we check all production quality and packaging at the final inspection.

5. Each process should be checked by relevant QC personnel.

Shipping

Payment Term: 30%TT Deposit + Delivery payment balance. ( Note: Specific can be discussed.) Support T/T, Western Union, Paypal Etc payment.

Shipping Terms: EXW(WENZHOU), FOB(Ningbo, Shanghai Port),CFR,CIF,DDP,DDU. We support international express transportation by land, sea and air